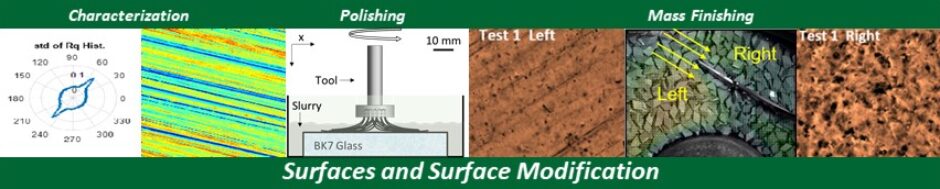

My research focuses on two main, complementary areas: surfaces and manufacturing. Analyzing the surface after manufacturing provides valuable insights into the physics of the process that created the part. Variations in surface topography can indicate fluctuations in processing conditions.

- Processes of interest include Ceramic additive manufacturing and abrasive processes (grinding, polishing, and loose abrasives)

- Surface topography, with a focus on advanced processing metrics, machine learning and AI-assisted interpretable surface classification, and understanding how a surface’s geometric topography affects its functionality.

Specific examples include

- A review paper on the approaches and challenges in surface imperfection detection and evaluation – paper details: http://10.0.3.248/j.cirp.2022.05.004

- A robust approach towards surface feature identification for interpretable classification challenges – presentation, paper details: https://doi.org/10.1016/j.jmsy.2023.08.002

- Assessment of Alumina parts printed via stereolithography (SLA) – presentation.

- Fiber based polishing tools – details (fiber tool)

- Mass finishing of freeform surfaces – Additional details can be found at this YouTube page and here details (vib finish)

- Polar plots for surface characterization and defect detection – details (surface char)

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

High Speed Videos of Vibratory Finishing

Videos referred to in the following paper(s)

- A. Sood,B. Mullany, “Advanced Surface Analysis to Identify Media-Workpiece Contact Modes in a Vibratory Finishing Processes”, Procedia Manufacturing, Volume 53,Pages 155-161, 2021.

- B. Mullany, H. Shahinian, J. Navare, F. Azimi, E. Fleischhauer, P. Tkacik, R. Keanini, “The application of computational fluid dynamics to vibratory finishing processes”, Annals of the CIRP, 66/1/2017, 309-312, 2017.

Sample orientated Normal to the media flow:

Sample orientated Tangential to the media flow: