Nimisha Patel, Graduated with M.S. (Envr. Engr.)

Undergraduate degree from India

Graduated in Aug. 2005.

Current Affiliation: Geomatrix Consultants

Abstract

This project is about hydraulic equivalency of prescribed RCRA caps versus earthen (evapotranspirative) final caps for sub-humid climates such as Michigan. The hydraulic equivalency will consider the effect of the waste layer and gas pressures that exist in actual final caps. Majority of previous research on this topic has been based on lysimeter designs that do not consider these effects. However, regulators only allow relatively low demonstrated percolation (~few mm/year) through the alternative cap before a permit is issued. Earthen caps have many advantages compared to conventional composite liner caps. These advantages include: cost savings; ability to grow deep rooted plants or trees on landfill cap for phytoremediation, long-term erosion control, fiber revenues, aesthetics; and more.

In this project, field-scale evapotranspirative caps were constructed at a landfill located near Detroit, Michigan. Two tests sections, 50 ft by 100 ft each, were built on the top of waste that has reached final elevations. Both test sections are made up of native soil (silty clay glacial till). The north test section is 4.5 ft thick and the south test section is 6 ft thick. In order to directly quantify the net percolation through the caps, a 20 ft x 20 ft x 2 ft deep vented (or pressure controlled) enclosure lysimeters were constructed within the middle of each of the test sections. Rest of the test section is on an existing waste that was placed in the cell in 1990s.

Field water balance data has been monitored by installing over 75 total sensors for the measurement of volumetric water contents, soil matric suctions, temperatures, and gas pressures. Nests of sensors were installed up-gradient and down-gradient of both test sections, as well as within the upper portions of the underlying waste. A pressure transducer was placed at the bottom of the lysimeters to quantify the percolation through he caps. This lysimeter design is significantly cheaper compared the EPA ACAP lysimeters. Climatic data has been collected using a meteorological station installed at the site.

Resulting Publication

Abstract

This project is about hydraulic equivalency of prescribed RCRA caps versus earthen (evapotranspirative) final caps for sub-humid climates such as Michigan. The hydraulic equivalency will consider the effect of the waste layer and gas pressures that exist in actual final caps. Majority of previous research on this topic has been based on lysimeter designs that do not consider these effects. However, regulators only allow relatively low demonstrated percolation (~few mm/year) through the alternative cap before a permit is issued. Earthen caps have many advantages compared to conventional composite liner caps. These advantages include: cost savings; ability to grow deep rooted plants or trees on landfill cap for phytoremediation, long-term erosion control, fiber revenues, aesthetics; and more.

In this project, field-scale evapotranspirative caps were constructed at a landfill located near Detroit, Michigan. Two tests sections, 50 ft by 100 ft each, were built on the top of waste that has reached final elevations. Both test sections are made up of native soil (silty clay glacial till). The north test section is 4.5 ft thick and the south test section is 6 ft thick. In order to directly quantify the net percolation through the caps, a 20 ft x 20 ft x 2 ft deep vented (or pressure controlled) enclosure lysimeters were constructed within the middle of each of the test sections. Rest of the test section is on an existing waste that was placed in the cell in 1990s.

Field water balance data has been monitored by installing over 75 total sensors for the measurement of volumetric water contents, soil matric suctions, temperatures, and gas pressures. Nests of sensors were installed up-gradient and down-gradient of both test sections, as well as within the upper portions of the underlying waste. A pressure transducer was placed at the bottom of the lysimeters to quantify the percolation through he caps. This lysimeter design is significantly cheaper compared the EPA ACAP lysimeters. Climatic data has been collected using a meteorological station installed at the site.

Resulting Publication

Abstract

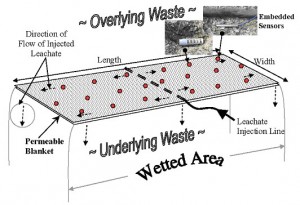

During the past two decades, the majority of geotechnical and geoenvironmental research related to landfills using in-situ sensing systems and field methods has been focused on securing the boundaries of the landfills - caps and liners. The proposed research is about sensing the "heart" of landfills, which is the waste representing over 99% of the landfill. The proposed approach will use the data collected from sensors embedded in permeable blankets primarily used for routine leachate recirculation to continuously and in real-time model the changes in the hydraulic and thermal conductivities of waste. This is critical because hydraulic and thermal properties of the waste change as a result of settlement, decomposition, age, and other operational variables. Currently, we have only limited knowledge on the long-term behavior and risks associated with "megafills" operated as bioreactors. In addition, the proposed approach will be independently confirmed by doing controlled lab experiments using a lab-scale physical model of landfill followed by comprehensive numerical modeling and by conducting field tracer tests at an instrumented landfill site in Michigan.

This project addresses uses of sensors coupled with computer modeling to optimize long-term performance of municipal solid waste landfills operated as bioreactors in the 21st century. The proposed research involves the use of data sensed from a variety of sensors embedded in permeable blankets devised by the PI and primarily used for leachate recirculation in bioreactor landfills to evaluate changes in in-situ hydraulic and thermal conductivities of waste on a continuous and real-time basis. In addition, tracer tests at an instrumented landfill and controlled lab tests are proposed to independently verify the findings of the sensor data using computer models. This multiyear project would allow the research team to collect data from a bioreactor landfill in Michigan that has been comprehensively instrumented over the last few years. The educational activities integrated within this research plan involve active learning projects using a plexi-glass landfill model and introducing waste management for high-school and undergraduate students. Active ties of Michigan State University with local high schools and special programs for minority and female students from the mid Michigan area would allow us to achieve participation of minorities and female students.

Resulting Publications

Abstract

During the past two decades, the majority of geotechnical and geoenvironmental research related to landfills using in-situ sensing systems and field methods has been focused on securing the boundaries of the landfills - caps and liners. The proposed research is about sensing the "heart" of landfills, which is the waste representing over 99% of the landfill. The proposed approach will use the data collected from sensors embedded in permeable blankets primarily used for routine leachate recirculation to continuously and in real-time model the changes in the hydraulic and thermal conductivities of waste. This is critical because hydraulic and thermal properties of the waste change as a result of settlement, decomposition, age, and other operational variables. Currently, we have only limited knowledge on the long-term behavior and risks associated with "megafills" operated as bioreactors. In addition, the proposed approach will be independently confirmed by doing controlled lab experiments using a lab-scale physical model of landfill followed by comprehensive numerical modeling and by conducting field tracer tests at an instrumented landfill site in Michigan.

This project addresses uses of sensors coupled with computer modeling to optimize long-term performance of municipal solid waste landfills operated as bioreactors in the 21st century. The proposed research involves the use of data sensed from a variety of sensors embedded in permeable blankets devised by the PI and primarily used for leachate recirculation in bioreactor landfills to evaluate changes in in-situ hydraulic and thermal conductivities of waste on a continuous and real-time basis. In addition, tracer tests at an instrumented landfill and controlled lab tests are proposed to independently verify the findings of the sensor data using computer models. This multiyear project would allow the research team to collect data from a bioreactor landfill in Michigan that has been comprehensively instrumented over the last few years. The educational activities integrated within this research plan involve active learning projects using a plexi-glass landfill model and introducing waste management for high-school and undergraduate students. Active ties of Michigan State University with local high schools and special programs for minority and female students from the mid Michigan area would allow us to achieve participation of minorities and female students.

Resulting Publications

Abstract

This paper presents a vertical pullout test (VPT) developed by the authors to measure the peak interface friction angle (δ) and adhesion (ca) between soil and planar geosynthetic products (e.g., geomembrane, geotextile). The key advantages of this test are: (1) relatively low capital cost for the equipment (as low as US$150); (2) relatively simple and time-efficient compared to the conventional methods; (3) the setup can be easily adapted by small conventional soil testing laboratories; and (4) the setup can be transported to the field for field-measurement for relatively quick evaluation of soils.

The experimental method developed in this research consists of: (1) measurement or estimation of the angle of internal friction (Φ') for the soil under consideration; (2) conducting vertical pullout tests at pre-defined surcharge loads on a representative sample of the planar geosynthetic product under consideration; and (3) using an analytical method to estimate the interface friction angle and adhesion using the data collected in Steps 1 and 2.

We verified this testing method by comparing the δ and ca obtained from the vertical pullout test to: (1) those measured using a conventional soil direct shear apparatus modified to also measure interface friction between planar geosynthetics and soil according to ASTM5321; and (2) values published in the literature. We tested three coarse-grained soils (coarse, medium, and well-graded sands) and three types of geomembranes (1.5mm thick smooth and textured HDPE and 1 mm thick smooth HDPE). We evaluated three sample sizes for the pullout test of the geomembranes (75mm x 150mm, 150mm x 150mm, and 300mm x 300mm).

The average peak interface friction angle measured from the VPT lied within ± 2° of the angle measured from the conventional direct shear apparatus. The interface friction angles measured using 150mm x 150mm sample for the VPT were more accurate compared to the other two sizes. If you need any further information, please contact Dr. Khire at khire@egr.msu.edu.

Resulting Publications

Abstract

This paper presents a vertical pullout test (VPT) developed by the authors to measure the peak interface friction angle (δ) and adhesion (ca) between soil and planar geosynthetic products (e.g., geomembrane, geotextile). The key advantages of this test are: (1) relatively low capital cost for the equipment (as low as US$150); (2) relatively simple and time-efficient compared to the conventional methods; (3) the setup can be easily adapted by small conventional soil testing laboratories; and (4) the setup can be transported to the field for field-measurement for relatively quick evaluation of soils.

The experimental method developed in this research consists of: (1) measurement or estimation of the angle of internal friction (Φ') for the soil under consideration; (2) conducting vertical pullout tests at pre-defined surcharge loads on a representative sample of the planar geosynthetic product under consideration; and (3) using an analytical method to estimate the interface friction angle and adhesion using the data collected in Steps 1 and 2.

We verified this testing method by comparing the δ and ca obtained from the vertical pullout test to: (1) those measured using a conventional soil direct shear apparatus modified to also measure interface friction between planar geosynthetics and soil according to ASTM5321; and (2) values published in the literature. We tested three coarse-grained soils (coarse, medium, and well-graded sands) and three types of geomembranes (1.5mm thick smooth and textured HDPE and 1 mm thick smooth HDPE). We evaluated three sample sizes for the pullout test of the geomembranes (75mm x 150mm, 150mm x 150mm, and 300mm x 300mm).

The average peak interface friction angle measured from the VPT lied within ± 2° of the angle measured from the conventional direct shear apparatus. The interface friction angles measured using 150mm x 150mm sample for the VPT were more accurate compared to the other two sizes. If you need any further information, please contact Dr. Khire at khire@egr.msu.edu.

Resulting Publications

Abstract

When Environmental Protection Agency’s (EPA) Resource Conservation and Recovery Act (RCRA) regulations came into effect in the late 80’s, the requirement of including a geomembrane (1 to 1.5 mm thick plastic sheet) in the final cap of municipal solid waste (MSW) landfills had a primary purpose of restricting infiltration into landfill to reduce leachate production and reduce gas emissions and minimize related environmental impacts. However, research data published during the last few years suggests that controlled addition of moisture to a landfill can be environmentally and economically beneficial. However, the impact of inclusion or exclusion of geomembrane in the final cap on gas emissions has not been evaluated. In order for environmental regulators to permit a final cap without a geomembrane, air quality impacts from gas emission must be evaluated. We propose to use flux chambers, a state-of-the-art device, to measure gas emissions from a bioreactor landfill cell. Exclusion of geomembrane from the final cap could potentially save landfill owners (and hence the broader population) over $1 billion in landfill capping costs over the next few decades.

The proposed research will fill in a key data gap related to quantification of landfill gas emissions from the final caps of MSW landfills operated as bioreactors. The final cap of an existing field-scale landfill bioreactor cell located in Michigan will be instrumented with: (1) gas probes to measure inorganic gas concentrations and pressure profile; and (2) flux chamber to measure inorganic and organic gas emissions from the surface. These gas emissions will be measured through a final cap containing geomembrane. The gas emissions will be measured to evaluate these three scenarios of the cap: (1) 1 cm2 hole made in the geomembrane; (2) relatively large size window cut in the geomembrane to simulate an earthen cap of clay; and (3) an earthen cap of sand. The bioreactor cell has been instrumented below the final cap as part of an ongoing research project.

The gas emissions data collected in this project will be comprehensive and unique due to the extent of the instrumentation already installed in the field-scale (~1 acre) bioreactor cell. Such comprehensive dataset will allow us to test gas generation and gas emission models requiring comprehensive physical, chemical, and biological input.

Abstract

When Environmental Protection Agency’s (EPA) Resource Conservation and Recovery Act (RCRA) regulations came into effect in the late 80’s, the requirement of including a geomembrane (1 to 1.5 mm thick plastic sheet) in the final cap of municipal solid waste (MSW) landfills had a primary purpose of restricting infiltration into landfill to reduce leachate production and reduce gas emissions and minimize related environmental impacts. However, research data published during the last few years suggests that controlled addition of moisture to a landfill can be environmentally and economically beneficial. However, the impact of inclusion or exclusion of geomembrane in the final cap on gas emissions has not been evaluated. In order for environmental regulators to permit a final cap without a geomembrane, air quality impacts from gas emission must be evaluated. We propose to use flux chambers, a state-of-the-art device, to measure gas emissions from a bioreactor landfill cell. Exclusion of geomembrane from the final cap could potentially save landfill owners (and hence the broader population) over $1 billion in landfill capping costs over the next few decades.

The proposed research will fill in a key data gap related to quantification of landfill gas emissions from the final caps of MSW landfills operated as bioreactors. The final cap of an existing field-scale landfill bioreactor cell located in Michigan will be instrumented with: (1) gas probes to measure inorganic gas concentrations and pressure profile; and (2) flux chamber to measure inorganic and organic gas emissions from the surface. These gas emissions will be measured through a final cap containing geomembrane. The gas emissions will be measured to evaluate these three scenarios of the cap: (1) 1 cm2 hole made in the geomembrane; (2) relatively large size window cut in the geomembrane to simulate an earthen cap of clay; and (3) an earthen cap of sand. The bioreactor cell has been instrumented below the final cap as part of an ongoing research project.

The gas emissions data collected in this project will be comprehensive and unique due to the extent of the instrumentation already installed in the field-scale (~1 acre) bioreactor cell. Such comprehensive dataset will allow us to test gas generation and gas emission models requiring comprehensive physical, chemical, and biological input.

Principal Investigator: Dr. Milind V. Khire, P.E. Funding Agency: Michigan State University

Abstract

Over 62 million tons of fly ash is annually generated in the U.S. alone from coal-fired power plants. Class F fly ash has been of very little use and has been typically disposed of in landfills at a significant cost. The key objective of this research project is to find alternate markets for re-use of the waste material. In this research we are conducting compaction tests, hydraulic conductivity tests, shear strength tests, and leachability tests on Class F fly ash with and without montmorrilonitic clay mixed at various fractions. The tests conducted so far indicate that addition of montmorrilonite to fly ash can reduce the hydraulic conductivity of fly ash to below 10-7cm/s. Thus, making it potentially suitable for environmental hydraulic barrier applications such as landfill liner, landfill caps, and vertical cutoff walls. We are also investigating the effect of montmorrilonitic clay on binding heavy metals such as boron, chromium, arsenic, and selenium that are typically present in most fly ash samples.

Abstract

Over 62 million tons of fly ash is annually generated in the U.S. alone from coal-fired power plants. Class F fly ash has been of very little use and has been typically disposed of in landfills at a significant cost. The key objective of this research project is to find alternate markets for re-use of the waste material. In this research we are conducting compaction tests, hydraulic conductivity tests, shear strength tests, and leachability tests on Class F fly ash with and without montmorrilonitic clay mixed at various fractions. The tests conducted so far indicate that addition of montmorrilonite to fly ash can reduce the hydraulic conductivity of fly ash to below 10-7cm/s. Thus, making it potentially suitable for environmental hydraulic barrier applications such as landfill liner, landfill caps, and vertical cutoff walls. We are also investigating the effect of montmorrilonitic clay on binding heavy metals such as boron, chromium, arsenic, and selenium that are typically present in most fly ash samples.

Abstract

Recirculation of leachate in municipal solid waste (MSW) landfills is commonly done for the following reasons:

Abstract

Recirculation of leachate in municipal solid waste (MSW) landfills is commonly done for the following reasons:

| Principal Investigator: | Dr. Milind V. Khire, P.E. |

| Funding Agency: | Waste Management, Inc. |

Abstract

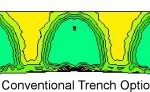

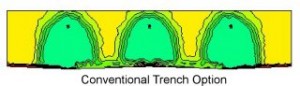

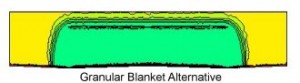

Leachate recirculation in municipal solid waste (MSW) landfills offers these key benefits: (1) reduction in leachate treatment and disposal costs; (2) accelerated decomposition and settlement of waste resulting in gain in airspace; (3) acceleration in gas production; and (4) potential reduction in post-closure care period and associated costs. Most common methods for long-term leachate recirculation in MSW landfills include vertical injection wells and horizontal trenches. Both of these methods result in non-uniform distribution of leachate. In addition, the amount of leachate that can be recirculated by these methods is not sufficient to get rid off all leachate typically produced by landfills located in humid regions. Non-uniform distribution of leachate leads to uneven landfill settlement and hence higher maintenance costs. The PI has developed a new design concept consisting of a horizontal blanket made up of relatively high hydraulic conductivity material(s) to recirculate leachate. Saturated/unsaturated leachate flow modeling conducted by the authors indicate that horizontal blankets made of relatively high hydraulic conductivity materials are capable of recirculating leachate at a rate up to an order greater than the conventional methods. In addition, the horizontal blanket is capable of achieving relatively uniform leachate distribution which is expected to reduce uneven settlement in a landfill. If the blanket is made up of recycled materials such as scrap tires, this design option can be cost-effective. In this project, we are evaluating the field-scale performance of a test section of horizontal blanket made up of scrap tires. This test section was built at an active landfill located in Michigan. The aerial dimensions of the test section were 55m by 9m (180ft by 30ft). The test section consisted of the following components, from bottom to top: a non-woven geotextile laid horizontally on the waste surface followed by approximately 0.6m (2ft) thick shredded scrap tires followed by a non-woven geotextile. The uppermost geotextile was covered by MSW. A 9m (30 ft) long perforated HDPE pipe was installed at the center of the test section, parallel to the short side, for injecting leachate. Fifteen uniformly spaced moisture content sensors were installed at the bottom of the test section to detect the movement of injected leachate. A load sensor was installed to monitor the weight (or stress) of the waste placed on the test section. A digital pressure gauge and a magnetic flow meter were installed to monitor the leachate head and flow. All sensors including meteorological data sensors were connected to an on-site data logger programmed to take readings every minute or at an appropriate desired frequency. A relatively high flow pump was used to conduct leachate recirculation trials at leachate flows ranging from 15 to 140 gpm (3.4 to 32 m³/hr). The data collected from the sensors indicated that leachate traveled across the entire length of the test section through the tires (~30m). The amount of time required for leachate travel across the blanket varied from 10 minutes to over 90 minutes depending upon the leachate flow. The data collected from the field trial verified the numerical modeling results and proved that horizontal blankets made up of scrap tires are cost-effective and are hydraulically efficient for recirculation of leachate in MSW landfills. Resulting Publications Haydar, M., and Khire, M. (2004), “Field-Scale Testing of Leachate Recirculation Blanket Made Up of Scrap Tires at a MSW Landfill,” Proceedings of the Nineteenth International Conference on Solid Waste Technology and Management, Philadelphia, March 2004, accepted. Haydar, M., and Khire, M. (2004), “Numerical Evaluation of Anisotropy and Heterogeneity of Waste Hydraulic Conductivity on Leachate Recirculation in MSW Landfills,” Proceedings of the Nineteenth International Conference on Solid Waste Technology and Management, Philadelphia, March 2004, accepted. Haydar, M., and Khire, M. (2006). "Geotechnical Sensor System to Monitor Injected Liquids in Landfills" Geotechnical Testing Journal, American Society of Testing of Materials, Vol. 29, No. 1, 1-12. Haydar, M., and Khire, M. (2005), "Leachate Recirculation Using Horizontal Trenches in Bioreactor Landfills" Journal of Geotechnical & Geoenvironmental Engineering, American Society of Civil Engineers, Vol. 131, No. 7, 837-847. Haydar, M., and Khire, M. (2005), "Numerical Evaluation of Heterogeneity and Anisotrophy of Waste Properties on Leachate Recirculation in Bioreactor Landfills" The Journal of Solid Waste Management & Technology, Vol. 30, No. 4, 233-243. Khire, M., and Haydar, M. (2004), "Leachate Recirculation in Bioreactor Landfills Using Geocomposite Drainage Material" Journal of Geotechnical & Geoenvironmental Engineering, American Society of Civil Engineers, in review.